The Role of Directional Control Valves in Pneumatic Systems

Pneumatic systems utilize compressed air to perform various mechanical tasks, offering efficiency and versatility in industrial applications.

Understanding the basics of pneumatic systems is crucial for engineers and technicians working in manufacturing, automation, and robotics. Here's a brief overview:

- Definition: Pneumatic systems are systems that use compressed air to transmit and control energy.

- Components: They consist of components such as compressors, actuators, valves, and air cylinders.

- Principles: Pneumatic systems operate on principles of pressure differentials and fluid dynamics.

- Advantages: They offer advantages like simplicity, low cost, and high reliability.

- Applications: Common applications include automation, material handling, and assembly lines.

- Maintenance: Regular maintenance is essential for optimal performance and longevity.

- Choosing Components: Selecting quality components is crucial for efficiency and safety. Consider the best directional control valve manufacturer for reliable operation.

Understanding the fundamentals of pneumatic systems lays the groundwork for designing, operating, and maintaining efficient industrial processes.

Functionality of Directional Control Valves in Pneumatics

Imagine a complex dance of pressurized air, precisely directed to bring machines to life. At the heart of this choreography lies the directional control valve, the unsung hero of pneumatics. But what exactly does it do? Let's dive into its key functionalities:

- Direction Master: As the name suggests, this valve dictates the flow path of compressed air. Imagine a city with traffic lights; the valve acts as the controller, directing air to different chambers in a pneumatic cylinder, enabling movement in various directions.

- Power Play: By connecting pressurized air to specific ports, the valve controls the force exerted by the cylinder. This allows for precise control of speed, pressure, and force, crucial for delicate operations.

- Flow Friend or Foe: The valve can not only direct but also block the flow of air. This allows for stopping, holding, and reversing movements, adding versatility and safety to pneumatic systems.

- Multitasking Marvel: Directional control valves come in various configurations, offering different port combinations and actuation methods (manual, electrical, pneumatic). This versatility allows them to adapt to diverse applications.

As a leading directional control valve manufacturer, we offer a vast selection of high-performance valves, backed by years of experience and unwavering commitment to quality. Explore our offerings and discover the perfect valve to orchestrate your pneumatic symphony.

Controlling Air Flow: The Significance of Directional Control Valves

Imagine the complex machinery in factories, construction sites, and even amusement parks. Behind their precise movements lies a silent maestro: the directional control valve.

What they do:

- Direct compressed air flow: These valves act as traffic controllers, channeling the air to various parts of the system.

- Start, stop, and regulate: They activate pistons, rotate motors, and even hold positions with pinpoint accuracy.

- Boost efficiency and safety: By controlling air flow, they optimize energy usage and prevent uncontrolled movements, ensuring smooth and safe operation.

Why they matter:

- Versatility: Valves come in various configurations and sizes, adapting to a wide range of applications.

- Precision control: They enable exact movements, crucial for tasks like robotic welding or intricate material handling.

- Durability: Built to withstand demanding environments, they offer reliable performance over time.

Finding the best:

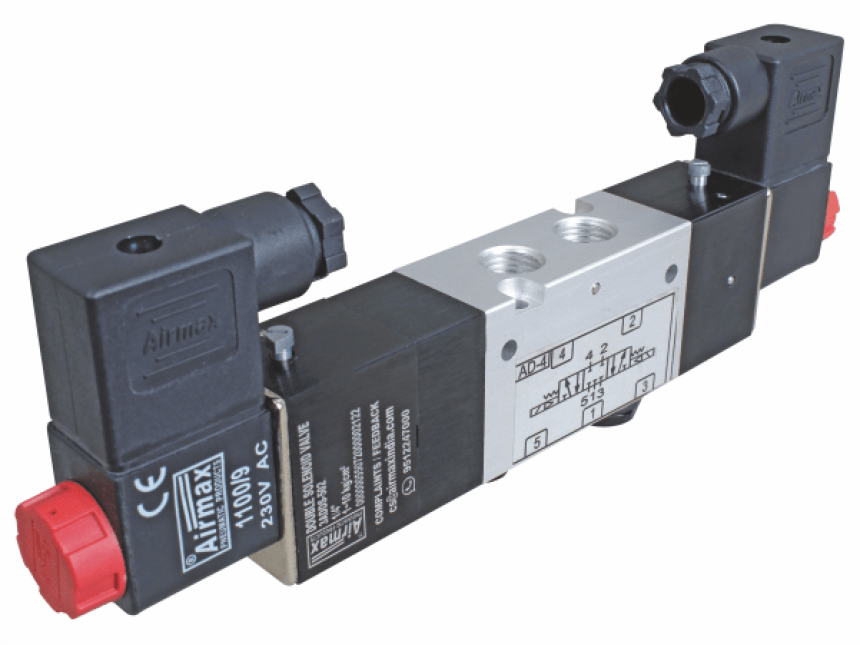

Selecting the right directional control valve is essential. Look for a manufacturer like Airmax Pneumatic, renowned for:

- Extensive product range: Catering to diverse needs across industries.

- Unwavering quality: Utilizing premium materials and rigorous testing for optimal performance.

- Expert support: Providing guidance and technical assistance to ensure the perfect fit.

With the right directional control valve, you unlock the power of compressed air, propelling your operations to new heights.

Types of Pneumatic Actuators Utilizing Directional Control Valves

Pneumatic actuators, powered by compressed air, bring versatility and efficiency to various applications. But to control this force, you need the right directional control valve manufacturer. Let's explore different actuator types and how valves govern their movement:

Linear Actuators:

- Piston: Powerful and precise, ideal for pushing, pulling, and lifting heavy loads.

- Diaphragm: Compact and flexible, suitable for precise positioning in smaller spaces.

- Rack & Pinion: Converts linear motion to rotary motion, often used for gripping or clamping.

Rotary Actuators:

- Vane: High torque at low speeds, perfect for opening/closing valves or turning mechanisms.

- Gear Motor: Precise rotational control over a wider speed range, ideal for conveyor systems or robotic applications.

Choosing the Right Valve:

Each actuator type requires specific valve configurations to achieve desired movement. Consider factors like:

- Number of ports: 2-way valves control on/off, while 3-way or 4-way valves offer more complex flow management.

- Actuation method: Manual, solenoid-operated, or pilot-operated valves provide varying levels of control and automation.

- Flow rate and pressure: Choose valves capable of handling the required air volume and pressure for optimal performance.

Finding the Best Directional Control Valve Manufacturer:

With so many options, selecting the right manufacturer is crucial. Look for a company with:

- Extensive product range: Offering various valve types and configurations to match your specific needs.

- Proven quality and reliability: A track record of producing durable, high-performance valves.

- Technical expertise: Experienced engineers to assist with valve selection and application support.

By understanding different pneumatic actuators and their control through valves, you can make informed decisions. When it comes to finding thebest directional control valve manufacturer, prioritize quality, expertise, and a product range that empowers your application's success.

Applications of Directional Control Valves in Pneumatic Machinery

The invisible workhorses of industry, directional control valves, are crucial for the precise movement and control of pneumatic machinery. By regulating the flow of compressed air, these valves play a vital role in diverse applications across various sectors. Here's a glimpse into their key functions:

- Industrial Automation: From robotic arms to assembly lines, best directional control valve manufacturer valves orchestrate complex movements, ensuring accuracy and speed. Think pick-and-place operations, material handling, and precise positioning – all powered by these valves.

- Manufacturing Efficiency: In pneumatic presses, textile machinery, and food processing equipment, valves control pressures and actuate cylinders, streamlining production processes and boosting efficiency.

- Mobile Equipment Operation: Construction cranes, agricultural machinery, and even delivery drones rely on directional control valves for smooth operation. They enable lifting, steering, and other critical functions with precision and responsiveness.

- Energy Savings: Advanced valves offer pressure regulation and flow control, optimizing energy consumption in pneumatic systems. This translates to cost savings and a reduced environmental footprint.

The choice of the right directional control valve is crucial for optimal performance and efficiency. Look for a manufacturer with a proven track record, a diverse product portfolio, and commitment to innovation. After all, choosing the best directional control valve manufacturer can significantly impact your machinery's performance and your bottom line.

Sequential Control: How Directional Valves Coordinate Pneumatic Operations

Imagine a complex, multi-step process executed flawlessly by compressed air. That's the power of sequential control in pneumatics, achieved through the precise coordination of directional control valves. These valves act as maestros, directing the flow of air to power cylinders and actuators in a pre-defined order, ensuring smooth, efficient operation.

How it Works:

- Strategic Valve Placement: Different types of directional valves (solenoid, pilot-operated, etc.) are strategically placed in the pneumatic circuit.

- Control Signals: Each valve receives control signals, either electrical, pneumatic, or mechanical, triggering specific actions.

- Flow Management: Based on the signal, the valve directs compressed air to specific ports, powering actuators in a predetermined sequence.

- Synchronized Movement: Cylinders extend, retract, or hold positions in perfect harmony, achieving the desired task.

Benefits of Sequential Control:

- Enhanced Precision: Complex processes are executed with pinpoint accuracy and repeatability.

- Increased Efficiency: Optimized air usage reduces energy consumption and costs.

- Improved Safety: Controlled sequences minimize risks and ensure operator safety.

- Greater Versatility: Adaptable to various applications with diverse actuation needs.

For reliable, high-performance directional control valves, look no further than Airmax Pneumatic, a leading manufacturer renowned for its innovative designs, exceptional quality, and commitment to customer satisfaction. With our valves, you can orchestrate intricate pneumatic operations with confidence, maximizing efficiency and achieving outstanding results.

Efficiency and Precision: Optimizing Pneumatic Systems with Directional Control Valves

The heart of any pneumatic system beats with the rhythm of its directional control valves. These unsung heroes manage the flow and direction of compressed air, dictating the performance and efficiency of countless industrial applications. But how can you ensure your system is operating at its peak? Here's how:

Precision Control:

- Match the valve to the task: Different valve types offer varied flow characteristics. Partner with the best directional control valve manufacturer to select the perfect valve for your specific pressure, flow, and response time requirements.

- Minimize internal leakage: Opt for valves with tight tolerances and high-quality seals to prevent compressed air loss and maintain precise actuation.

- Utilize advanced features: Consider valves with built-in flow control or soft-start/stop functionalities for even finer control and reduced wear and tear.

Efficiency Boosters:

- Right-size your valves: Oversized valves waste energy. Partner with your best directional control valve manufacturer to determine the exact flow capacity needed for each application.

- Minimize pressure drops: Choose valves with streamlined internal pathways and low flow resistance to reduce energy consumption.

- Embrace energy-saving technologies: Explore valves with features like low-power solenoids or integrated pressure regulators to further optimize energy usage.

By prioritizing both precision and efficiency through strategic valve selection and collaboration with a best directional control valve manufacturer, you can unlock the full potential of your pneumatic systems, maximizing performance while minimizing energy consumption.

This Article is written to accelerate businesses. JOIN The Community Now! Fuel your business success with Grow Media Digital! 🚀 Tailoring expert strategies, from SEO to social media, they ensure a perfect fit for your needs. With an innovative approach, they stay ahead of trends, guaranteeing measurable growth. Visit growmedia.digital to rise your business to new heights.